In the construction of a nuclear power plant, achieving efficiency and safety requires meticulous planning and adherence to specific protocols. One critical aspect is the hierarchical arrangement of building services, particularly in shared distribution zones. This hierarchy ensures optimal functionality, maintenance ease, and safety compliance.

The Importance of Service Hierarchy

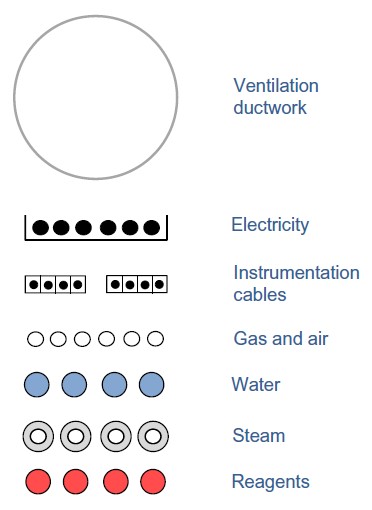

The arrangement of services within a shared distribution zone is not arbitrary but follows a logical sequence established by industry specialists. This hierarchy maximizes space utilization while addressing practical and safety considerations. Below is an outline of the typical hierarchy:

- Ventilation Ductwork

- Ventilation ductwork is positioned at the highest level in shared zones. Its placement at the top is due to its large cross-sectional area, which can be significant in size. By allocating this position, ductwork remains unobstructed, ensuring efficient airflow distribution throughout the facility.

- Electricity and Instrumentation Cable Trays

- Beneath the ductwork are the cable trays for electrical and instrumentation systems. This arrangement is practical for several reasons:

- Maintenance: Cables are virtually maintenance-free, so their placement at height does not pose significant access challenges.

- Safety: Positioning cables above other services minimizes the risk of water exposure, which could compromise electrical integrity.

- Beneath the ductwork are the cable trays for electrical and instrumentation systems. This arrangement is practical for several reasons:

- Gas Services

- Gas service positioning allows for some flexibility but is typically above wet services. This placement facilitates simplified access to valves for maintenance and operational needs.

- Wet Services

- Wet services, including water and other fluid-carrying pipework, are placed below cables and gas services. This arrangement ensures that any potential leaks do not affect critical systems above.

- Reagents and Acidic Services

- Among wet services, reagent and acidic pipework occupy the lowest tier. This precautionary measure prevents damage from potential leaks, protecting other services from corrosive substances.

Special Considerations

While this hierarchy serves as a standard guideline, certain aspects demand close attention during the planning and installation phases:

- Electrical and Instrumentation Cable Separation: To prevent electromagnetic interference (EMI), sufficient spacing between electrical power cables and instrumentation cables is essential. Improper placement could disrupt sensitive instrument signals, compromising plant operations.

- Custom Adaptations: Site-specific requirements or constraints may necessitate deviations from the standard hierarchy. However, these changes must be carefully evaluated to maintain safety and operational efficiency.

Conclusion

The service hierarchy in nuclear power plant construction exemplifies the industry’s commitment to precision and safety. By following this logical arrangement, engineers and contractors can ensure seamless integration of critical systems while minimizing risks. At REMARS MEP Engineering Ltd., we understand the importance of adhering to these protocols and bring our expertise to deliver top-quality mechanical, electrical, and piping solutions tailored to the unique demands of nuclear power projects.

For more insights and expert guidance on MEP installations, visit our blog or contact us today!